CGS Venturi/Multi-Venturi

Multiscrub - H™

| |

The only CGS scrubber with a multi-venturi

deck and a mist separator for a horizontal gas flow. It provides

the maximum flexibility for system layout since the multi-venturi

deck is effective for either a vertical or horizontal gas flow.

Manually or automatically adjustable decks are available for applications

where variations in flow rates are expected or pressure drop adjustments

are necessary.

Dust

laden gases are directed through the multi-venturi deck comprised

of parallel pipes. Scrubbing liquid is introduced co-currently with

the gas stream utilizing low pressure, large orifice nozzles. Pipes

are supported by scalloped plates on both sides and are free to

rotate and vibrate during operation to eliminate build-up problems.

The accelerating gas through the venturies atomizes the liquid droplets

into smaller ones resulting in the impaction of dust particles on

the liquid droplets. Scrubbed gases are then evenly distributed

by an impingement bench or turning vanes before they enter predemist

baffles and a chevron type demister. A Sloped bottom minimizes any

build-up problems. The Slurry is discharged through the bottom and

the dewatered, scrubbed gases are exhausted via the outlet with

orientations to suit system layout. Dust

laden gases are directed through the multi-venturi deck comprised

of parallel pipes. Scrubbing liquid is introduced co-currently with

the gas stream utilizing low pressure, large orifice nozzles. Pipes

are supported by scalloped plates on both sides and are free to

rotate and vibrate during operation to eliminate build-up problems.

The accelerating gas through the venturies atomizes the liquid droplets

into smaller ones resulting in the impaction of dust particles on

the liquid droplets. Scrubbed gases are then evenly distributed

by an impingement bench or turning vanes before they enter predemist

baffles and a chevron type demister. A Sloped bottom minimizes any

build-up problems. The Slurry is discharged through the bottom and

the dewatered, scrubbed gases are exhausted via the outlet with

orientations to suit system layout.

|

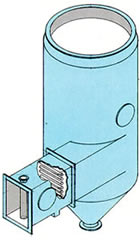

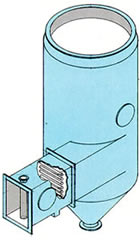

Multiscrub- C™

(204

KB) |

This unit incorporates CGS' unique

multi-venturi design and a conventional cyclonic mist separator.

It offers high collection efficiencies at low pressure drops with

low liquid requirements.

Standard units are furnished with a fixed multi-venturi deck comprised

of parallel pipes. Manually or automatically adjustable decks are

available for applications where variations in flow rates are expected

or pressure drop adjustments are necessary.

Dust laden gases enter the vertical or horizontal inlet of the

unit and are directed through the multi-venturi deck. Scrubbing

liquid is introduced co-currently with the gas stream utilizing

low pressure, large orifice nozzles. The accelerating gas through

the venturies atomizes the liquid droplets into smaller ones, resulting

in the impaction of dust particles on the liquid droplets.  The

scrubbed gases are then directed into the cyclonic separator where

separation of the gases and free liquid droplets takes place. The

slurry is discharged through the bottom and the dewatered, scrubbed

gases are exhausted via the outlet with orientations to suit system

layout. The

scrubbed gases are then directed into the cyclonic separator where

separation of the gases and free liquid droplets takes place. The

slurry is discharged through the bottom and the dewatered, scrubbed

gases are exhausted via the outlet with orientations to suit system

layout. |

Total System Responsibility:

- Consulting

- Stack Testing

- Design Engineering

|

- Manufacturing

- Installation

- Erection

|

- Start-up

- Replacement Parts

- Detail Fabrication Drawings (for manufacturing by local shops)

|

Typical Applications:

- Acid Mist

- Absorption

- (SO2/Cl2/HF/HCl/

H2S/NH3/ClO2/TRS)

- Antimony Oxide

- Autoclaves

- Blow Tanks

- Blue Haze Reduction

- Boilers

- Building Products Mfg.

- Calciners

- Cereal Cookers/Dryers

- Coke Ovens

- Cupolas

- Crushers

|

- Dissolving Tank Vents

- Dryers

- Electric Arc Furnaces

- Fumes

- Grinding

- Incinerators

- Lime Hydrators

- Lime Kilns

- Lime Slakers

- Packaging

- Odor Control

- Oil Mists

- Opacity Elimination

- Ovens

- Pelletizing

|

- Recovery Boilers

- Recovery Furnaces

- Refining

- Rendering

- Retrofits/Upgrades

- Roasters

- Sand Systems

- Scarfing

- Sewage Sludge

- Sintering

- Smelters

- Transfer Points

- VOC's

|

Industries Served:

- Aggregates

- Automobile

- Boilers

- Building Products

- Cement

- Chemicals

- Coal

- Detergents

- Electric Utility

- Ethanol

|

- Fertilizers

- Flue Gas Desulfurization

- Food

- Foundry

- Grain Processing

- Incineration

- Lime

- Mining

- Paints/Pigments

- Petroleum

|

- Pharmaceutical

- Plastics

- Potash

- Printing

- Pulp & Paper

- Sewage Treatment

- Steel

- Taconite

- Textiles

- Wood Products

|

<<Ventriscrub

Centrifugal/Vane

| Impingement | Dynamic/Wet

Fan | Venturi | Multi-Venturi

^Top

of Page

Dust

laden gases are directed through the multi-venturi deck comprised

of parallel pipes. Scrubbing liquid is introduced co-currently with

the gas stream utilizing low pressure, large orifice nozzles. Pipes

are supported by scalloped plates on both sides and are free to

rotate and vibrate during operation to eliminate build-up problems.

The accelerating gas through the venturies atomizes the liquid droplets

into smaller ones resulting in the impaction of dust particles on

the liquid droplets. Scrubbed gases are then evenly distributed

by an impingement bench or turning vanes before they enter predemist

baffles and a chevron type demister. A Sloped bottom minimizes any

build-up problems. The Slurry is discharged through the bottom and

the dewatered, scrubbed gases are exhausted via the outlet with

orientations to suit system layout.

Dust

laden gases are directed through the multi-venturi deck comprised

of parallel pipes. Scrubbing liquid is introduced co-currently with

the gas stream utilizing low pressure, large orifice nozzles. Pipes

are supported by scalloped plates on both sides and are free to

rotate and vibrate during operation to eliminate build-up problems.

The accelerating gas through the venturies atomizes the liquid droplets

into smaller ones resulting in the impaction of dust particles on

the liquid droplets. Scrubbed gases are then evenly distributed

by an impingement bench or turning vanes before they enter predemist

baffles and a chevron type demister. A Sloped bottom minimizes any

build-up problems. The Slurry is discharged through the bottom and

the dewatered, scrubbed gases are exhausted via the outlet with

orientations to suit system layout.

The

scrubbed gases are then directed into the cyclonic separator where

separation of the gases and free liquid droplets takes place. The

slurry is discharged through the bottom and the dewatered, scrubbed

gases are exhausted via the outlet with orientations to suit system

layout.

The

scrubbed gases are then directed into the cyclonic separator where

separation of the gases and free liquid droplets takes place. The

slurry is discharged through the bottom and the dewatered, scrubbed

gases are exhausted via the outlet with orientations to suit system

layout.