Quick Contact

CGS Wet Electrostatic Precipitators

|

|

|

|

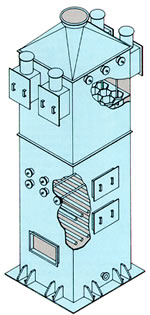

CG - WESP™ Our Wet Electrostatic Precipitator provides 99% + removal efficiency for submicron particles at minimum pressure drop. For applications where a precleaning stage is required, CGS' Multiventuri Scrubber/Gas Absorber is included. CG-WESP utilizes an open Hexagonal Grid type Collector with 6" clearance between the surfaces. This Honeycomb type Collector Assembly provides the most powerful and structurally sound design with maximum collector surface area. Collector Grid Surfaces are not subjected to any pressure differential because the gases pass thru them on both sides. Our unique design does not require any tube sheets. Hence, a greater cross sectional area without any wasted space is provided. Two levels of gas distributors ensure uniform flow within the unit. A Flushing System incorporates spray nozzles that provide continuous cleaning with minimum liquid requirements in a co-current mode. |

|

|

The precipitator collector grid has two major components: the ionizing rods (which are under high voltage) and the collector grid (which is grounded). The ionizing rods are suspended between the collector tube surfaces in such a manner as to be equidistant from all surfaces. The rods are under high voltage. Points on the rods create an ionization corona which send a flow of electrons across the space between the rods and the collector surface. As particles pass through this corona, they pick up a charge. The collector surfaces are grounded at a charge opposite that of the particles. The charged particles are repelled by the like charged rods and attracted by the oppositely charged collector surfaces. In this manner, the particles are attracted to the collector plate walls where they coalesce and are removed by the water which flushes them away. A series of spray headers with nozzles are provided for intermittent cleaning at the top of the unit. Our high voltage insulators are located on the clean side at the top for problem-free operation. Each CG-WESP is furnished with high voltage internals consisting of Rigid Electrode type Ionizers, Supports, Insulators, Bus Bar and Oil filled Transformer/Rectifier Set Controllers with a Saturable Core Reactor. Various materials of construction are available to suit corrosive services. |

|

Total System Responsibility:

|

|

|

Typical Applications:

|

|

|

Industries Served:

|

|

|