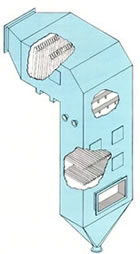

CGS Multi-Venturi Gas Absorbers

Multiscrub - V™

| |

The heart of this technology is CGS'

unique MULTISCRUB deck, which is designed based on the principle

of multiple venturies. The MULTISCRUB rod deck consists of a multitude

of pipes placed parallel to each other at equal distances to form

a certain number of parallel venturies. The number of venturies

for each deck and total number of decks are selected based on your

efficiency requirements. The number of venturies can easily be altered

by simply removing or adding pipes to the deck to suit your application.

CGS' MULTISCRUB deck can be applied to the scrubbing of particulate

and/or gaseous pollutants. Unlike any conventional PACKED BED ABSORBER,

CGS' MULTISCRUB-V is capable of utilizing slurries containing high

concentrations of solids without plugging problems. The MULTISCRUB

decks are self cleaning.

For dust removal, the gas flow can be upward, downward or horizontal

to suit any desired system configuration. |

|  For

gas absorption, each MULTISCRUB deck is placed in a horizontal position

to maximize efficiency. The pollutant laden gas enters the unit

radially near the bottom and is directed upwards through the MULTISCRUB

decks. Scrub liquor is sprayed from the top utilizing large orifice,

low pressure nozzles. A turbulent contacting zone between gas and

scrub liquor is maintained on top of each MULTISCRUB deck to enhance

mass transfer. Intimate contact between the liquid and the gas takes

place in this area in a counter current mode, resulting in the absorption

of the pollutants into the scrub liquor. The cleaned gas passes

through a mist eliminator, which removes most of its entrained liquid

droplets, before exiting the unit. The scrub liquor flows to the

integral or external sump and is recycled, in part or in whole,

back to the top of the tower. At least a slip stream of the scrub

liquor must be discharged out of the scrub liquor loop to get rid

of the absorbed pollutants. Chemicals may be added to the scrub

liquor to enhance the efficiency and/or to neutralize the absorbed

pollutants. For

gas absorption, each MULTISCRUB deck is placed in a horizontal position

to maximize efficiency. The pollutant laden gas enters the unit

radially near the bottom and is directed upwards through the MULTISCRUB

decks. Scrub liquor is sprayed from the top utilizing large orifice,

low pressure nozzles. A turbulent contacting zone between gas and

scrub liquor is maintained on top of each MULTISCRUB deck to enhance

mass transfer. Intimate contact between the liquid and the gas takes

place in this area in a counter current mode, resulting in the absorption

of the pollutants into the scrub liquor. The cleaned gas passes

through a mist eliminator, which removes most of its entrained liquid

droplets, before exiting the unit. The scrub liquor flows to the

integral or external sump and is recycled, in part or in whole,

back to the top of the tower. At least a slip stream of the scrub

liquor must be discharged out of the scrub liquor loop to get rid

of the absorbed pollutants. Chemicals may be added to the scrub

liquor to enhance the efficiency and/or to neutralize the absorbed

pollutants.

Simultaneous particulate scrubbing and gas absorption can be achieved

by incorporating a high pressure drop MULTISCRUB deck for particulate

removal and a combination of required number of low pressure drop

absorption decks and/or spray zone in the same unit. |

Total System Responsibility:

- Consulting

- Stack Testing

- Design Engineering

|

- Manufacturing

- Installation

- Erection

|

- Start-up

- Replacement Parts

- Detail Fabrication Drawings (for manufacturing by local shops)

|

Typical Applications:

- Acid Mist

- Absorption

- (SO2/Cl2/HF/HCl/

H2S/NH3/ClO2/TRS)

- Antimony Oxide

- Autoclaves

- Blow Tanks

- Blue Haze Reduction

- Boilers

- Building Products Mfg.

- Calciners

- Cereal Cookers/Dryers

- Coke Ovens

- Cupolas

- Crushers

|

- Dissolving Tank Vents

- Dryers

- Electric Arc Furnaces

- Fumes

- Grinding

- Incinerators

- Lime Hydrators

- Lime Kilns

- Lime Slakers

- Packaging

- Odor Control

- Oil Mists

- Opacity Elimination

- Ovens

- Pelletizing

|

- Recovery Boilers

- Recovery Furnaces

- Refining

- Rendering

- Retrofits/Upgrades

- Roasters

- Sand Systems

- Scarfing

- Sewage Sludge

- Sintering

- Smelters

- Transfer Points

- VOC's

|

Industries Served:

- Aggregates

- Automobile

- Boilers

- Building Products

- Cement

- Chemicals

- Coal

- Detergents

- Electric Utility

- Ethanol

|

- Fertilizers

- Flue Gas Desulfurization

- Food

- Foundry

- Grain Processing

- Incineration

- Lime

- Mining

- Paints/Pigments

- Petroleum

|

- Pharmaceutical

- Plastics

- Potash

- Printing

- Pulp & Paper

- Sewage Treatment

- Steel

- Taconite

- Textiles

- Wood Products

|

Packed

Towers | Multi-Venturi | Marble Bed | Tray

Towers | Wet FGD Systems | Carbon Adsorbers

^Top

of Page

For

gas absorption, each MULTISCRUB deck is placed in a horizontal position

to maximize efficiency. The pollutant laden gas enters the unit

radially near the bottom and is directed upwards through the MULTISCRUB

decks. Scrub liquor is sprayed from the top utilizing large orifice,

low pressure nozzles. A turbulent contacting zone between gas and

scrub liquor is maintained on top of each MULTISCRUB deck to enhance

mass transfer. Intimate contact between the liquid and the gas takes

place in this area in a counter current mode, resulting in the absorption

of the pollutants into the scrub liquor. The cleaned gas passes

through a mist eliminator, which removes most of its entrained liquid

droplets, before exiting the unit. The scrub liquor flows to the

integral or external sump and is recycled, in part or in whole,

back to the top of the tower. At least a slip stream of the scrub

liquor must be discharged out of the scrub liquor loop to get rid

of the absorbed pollutants. Chemicals may be added to the scrub

liquor to enhance the efficiency and/or to neutralize the absorbed

pollutants.

For

gas absorption, each MULTISCRUB deck is placed in a horizontal position

to maximize efficiency. The pollutant laden gas enters the unit

radially near the bottom and is directed upwards through the MULTISCRUB

decks. Scrub liquor is sprayed from the top utilizing large orifice,

low pressure nozzles. A turbulent contacting zone between gas and

scrub liquor is maintained on top of each MULTISCRUB deck to enhance

mass transfer. Intimate contact between the liquid and the gas takes

place in this area in a counter current mode, resulting in the absorption

of the pollutants into the scrub liquor. The cleaned gas passes

through a mist eliminator, which removes most of its entrained liquid

droplets, before exiting the unit. The scrub liquor flows to the

integral or external sump and is recycled, in part or in whole,

back to the top of the tower. At least a slip stream of the scrub

liquor must be discharged out of the scrub liquor loop to get rid

of the absorbed pollutants. Chemicals may be added to the scrub

liquor to enhance the efficiency and/or to neutralize the absorbed

pollutants.